GUH-3540, 3580, 35100, 35150

Paragon USA | Universal Cylindrical Grinding Machines, CNC (Heavy Duty)

Every Paragon cylindrical grinder is designed and manufactured based on the following management concepts: Application of the newest technologies and innovation, endless improvement and progress and customer satisfaction. Assembly is carried out in strict compliance with ISO 9001 directives. All machine bases are manufactured from high quality Meehanite cast iron with a low center of gravity.

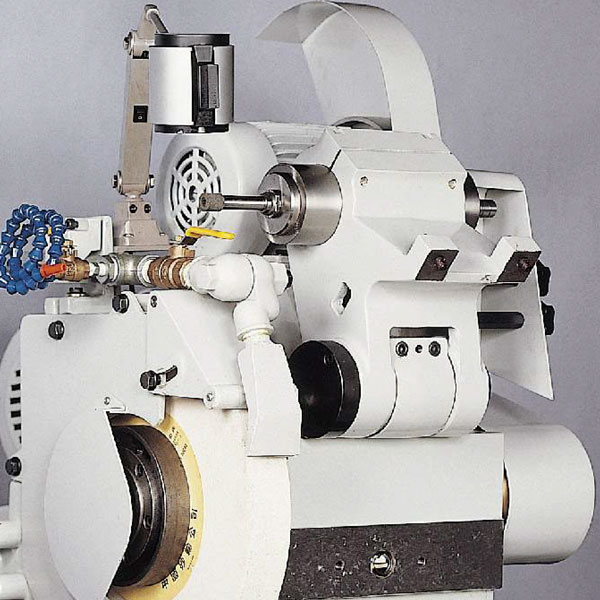

Universal wheel-head: Rigid and precise with a powerful 5-hp motor achieving peripheral speed 45m/s. Equipped with class C1 ballscrew (40mm dia.) and Heidenhain sub-μm linear scale with full close loop feedback.

Overall, the machine achieves +/- 0.5 μm repeatability accuracy

Grinding Spindle: Made of high quality alloy steel (SNCM-439).

Hydrostatic Bearings: No metal to metal friction, no overheat and no deformation and no oil leakage. The hydraulic and lubrication system has independent temperature control, providing minimum thermal displacement.

Hydrostatic Guideways: Hand scraped and features an oil lubrication system which reduces the metal friction and guarantees constant high accuracy.

Workhead: A rigid design, driven by servo motor, features reliable and precise operation. NN roller bearings and angular contact bearings in the workhead spindle reduce edge stress and friction, improving concentricity and surface finish of work piece. The table is enabled to swivel between 30° (clockwise) ~ 90° (counterclockwise).

Tailstock: Flexible and easy operation, equipped with hydraulic actuated barrel retraction by foot peddle and manual handle for easy workpiece loading and unloading. (M.T.4 Taper Center) Center pressure can be adjusted for high precision for small and thin workpieces.

CNC Controller: Rexroth MTX Micro color screen with the latest technology in digital control system. Powerful processor can shaorten CNC and PLC processing time. Compact multi-server drives, which smaller installing space and high processing accuracy.

Paragon’s self developed conversational interface software can get users started quickly.

Universal wheel-head: Rigid and precise with a powerful 5-hp motor achieving peripheral speed 45m/s. Equipped with class C1 ballscrew (40mm dia.) and Heidenhain sub-μm linear scale with full close loop feedback.

Overall, the machine achieves +/- 0.5 μm repeatability accuracy

Grinding Spindle: Made of high quality alloy steel (SNCM-439).

Hydrostatic Bearings: No metal to metal friction, no overheat and no deformation and no oil leakage. The hydraulic and lubrication system has independent temperature control, providing minimum thermal displacement.

Hydrostatic Guideways: Hand scraped and features an oil lubrication system which reduces the metal friction and guarantees constant high accuracy.

Workhead: A rigid design, driven by servo motor, features reliable and precise operation. NN roller bearings and angular contact bearings in the workhead spindle reduce edge stress and friction, improving concentricity and surface finish of work piece. The table is enabled to swivel between 30° (clockwise) ~ 90° (counterclockwise).

Tailstock: Flexible and easy operation, equipped with hydraulic actuated barrel retraction by foot peddle and manual handle for easy workpiece loading and unloading. (M.T.4 Taper Center) Center pressure can be adjusted for high precision for small and thin workpieces.

CNC Controller: Rexroth MTX Micro color screen with the latest technology in digital control system. Powerful processor can shaorten CNC and PLC processing time. Compact multi-server drives, which smaller installing space and high processing accuracy.

Paragon’s self developed conversational interface software can get users started quickly.

| Model | GUH-3540 CNC | GUH-3580 CNC | GUH-35100 CNC | GUH-35150 CNC |

| Swing over table (mm) | 350 | 350 | 350 | 350 |

| Distance between centers (mm) | 400 | 800 | 1000 | 1500 |

| Max. Grinding diameter (mm) | 320 | 320 | 320 | 320 |

| Max. Grinding wheel (mm) | 610 x 100 x 203.2 | 610 x 100 x 203.2 | 610 x 100 x 203.2 | 610 x 100 x 203.2 |

| Max. Load held between centers | 150-kg | 150-kg | 150-kg | 150-kg |

| Max. Grinding wheel speed | 45 m/s (60 opt.) | 45 m/s (60 opt.) | 45 m/s (60 opt.) | 45 m/s (60 opt.) |

| CNC Controller | FANUC / SIEMENS / MITSUBISHI | FANUC / SIEMENS / MITSUBISHI | FANUC / SIEMENS / MITSUBISHI | FANUC / SIEMENS / MITSUBISHI |

| X-axis min. resolution increment (mm) | 0.0001 | 0.0001 | 0.0001 | 0.0001 |

| X-axis rapid traverse speed | 6 m/min. | 6 m/min. | 6 m/min. | 6 m/min. |

| Z-axis min. resolution increment (mm) | 0.0001 | 0.0001 | 0.0001 | 0.0001 |

| Z-axis max. traverse speed | 8 m/min. | 8 m/min. | 8 m/min. | 8 m/min. |

| Z-axis can be swiveled manually in deg. | -0.5 ~ +5 | -0.5 ~ +5 | -0.5 ~ +5 | -0.5 ~ +5 |

| Workhead spindle speed (rpm) | 5 - 750 | 5 - 750 | 5 - 750 | 5 - 750 |

| Tailstock hyd. Sleeve retraction (mm) | 25 | 35 | 35 | 35 |

| Tailstock center | M.T.4 | M.T.4 | M.T.4 | M.T.4 |

| Wheel spindle motor | 20-hp | 20-hp | 20-hp | 20-hp |

| Wheel head feed (servo motor) | 3.0-kw | 3.0-kw | 3.0-kw | 3.0-kw |

| Table feed (servo motor) | 3.0-kw | 3.0-kw | 3.0-kw | 3.0-kw |

| Internal grinding motor | - | 1-hp | 1-hp | 1-hp |

| Machine dimensions (cm) | 303 x 200 x 226 | 404 x 200 x 226 | 440 x 200 x 226 | 504 x 200 x 226 |

| Machine weight | 6600-kg | 7000-kg | 7200-kg | 8500-kg |

Specifications subject to change. Please contact us for more information.

GMSi Group is partnered with CIT Direct Capital for fast financing

through an automated online process. Our GMSi direct link to

CIT Direct Capital

Financing brings you to a simple-to-complete application – it will take you less

than 5 minutes! – and you can see what the payment terms and monthly payment will

be.